San Antonio Stamped Concrete

Welcome to San Antonio’s foremost destination for Stamped Concrete services, where innovation and craftsmanship converge to create stunning and durable surfaces. As a leading Stamped Concrete contractor in San Antonio, we specialize in providing top-notch stamped concrete, pressed concrete, and comprehensive stamped concrete solutions. Our commitment is to transform ordinary surfaces into works of art, enhancing the aesthetic appeal and functionality of your spaces.

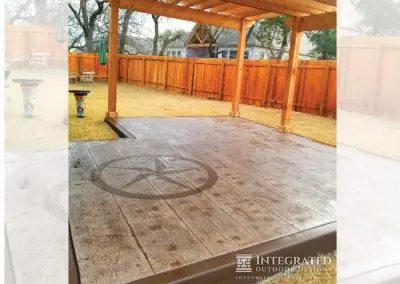

Decorative concrete, or stamped concrete, has become the latest trend in construction due to its versatility, durability, and beautiful designs to reflect natural wood, stone, and concrete with custom patterns, textures, colors, and score lines. It is also low-maintenance and affordable – perfect for patios, pool decks, driveways, and more.

We are excited to help you achieve your vision and ensure it becomes a reality, and we hope to open your eyes to a world of unparalleled distinction and choices. Nothing quite compares to the versatility and reliability of colored and stamped concrete. We are happy to use the Butterfield Color product. They have spent decades developing and perfecting the coloring and tools used in stamped concrete, resulting in their exclusive line of decorative concrete products.

Our team understands the importance of the project for you and your family. Our business is focused on the success of every project and the happiness of every customer who chooses Integrated Outdoor Designs.

Call or Text today to get your stamped concrete project started!

Stamped Concrete Services

Stamped Concrete Patio

Elevate your outdoor living experience with our expertly crafted stamped concrete patios. Choose from a variety of stamped concrete patterns and colors to create a unique and personalized space. Our skilled team ensures the durability and beauty of your stamped concrete patio, making it a focal point for gatherings and relaxation.

Stamped Concrete Driveway

Make a lasting first impression with a stamped concrete driveway. Our skilled craftsmen design and install stamped concrete driveways that not only withstand the elements but also add curb appeal to your property. Explore various patterns and finishes to match your style.

Stamped Concrete Sidewalk

Enhance the aesthetics of your property with a stamped concrete sidewalk. Our attention to detail and precision in stamping techniques create visually appealing and durable walkways that seamlessly blend with your landscape.

Stamped Concrete Floor

Bring the beauty of stamped concrete indoors with our innovative stamped concrete floor solutions. From residential spaces to commercial establishments, we offer a range of patterns and finishes to suit your interior design preferences.

We also do garage floors! Choose from a variety of colors using metallic epoxy or flake epoxy flooring.

Stamped Concrete Overlay

Revitalize existing concrete surfaces with our stamped concrete overlay services. Whether it’s a patio, driveway, or floor, our concrete overlay solutions provide a cost-effective way to achieve the look of stamped concrete without a complete overhaul.

Stamped Concrete Finishes

Decorative Concrete

Explore the world of decorative concrete with our extensive range of stamped patterns and finishes. Our decorative concrete solutions add a touch of sophistication to both indoor and outdoor spaces, creating a lasting impact.

Patterned Concrete

Choose from an array of intricate patterns to customize your stamped concrete surfaces. Our patterned concrete options allow you to express your unique style and transform ordinary spaces into extraordinary ones.

Textured Concrete

Experience the tactile appeal of textured concrete. Our textured finishes not only provide visual interest but also add depth and dimension to your stamped concrete surfaces, creating a dynamic and inviting atmosphere.

Ready to start your stamped concrete project?

The Stamped Concrete Process

Before you begin your selection process, you must have a basic understanding of the stamped concrete process.

Stamped Concrete Patterns

We have over 75 patterns to choose from. You can choose a unique color combination with each stamp that fits your design ideas.

Assuming you have chosen a primary location for your stamped concrete, you can now focus on your final product vision.

Stamped concrete can be broken into five basic pattern types:

- Brick

- Stone

- Slate, Wood

- Texture

These are just basic categories, but using these as a reference will help you determine which patterns to look at first.

One essential element to consider is complementing your hardscape rather than trying to “match” existing surfaces and the surroundings.

Stamped Concrete Colors

Now that you have chosen your pattern, we move on to color picking. Most stamped concrete has two colors: a base color and an accent color. There are two ways to create the base color for new concrete: integral color and color hardener. With either method, the end result of your stamped concrete will emphasize this color.

Integral Color: Integral color is mixed into the concrete in the truck. The color is added at the concrete plant or project site before pouring begins.

Integral color is the most common way to color concrete, and we offer a premium integral color system called Uni-Mix Integral Concrete Color.

The Uni-Mix Integral Color System is the preferred system of contractors, specifiers, and owners. Uni-Mix Integral Color Concrete Color has proprietary ingredients that make it unique.

Our competition will try to “match” our color, but it has been our experience and quite a few dissatisfied customers’ experiences that the color does not turn out the same.

A quick and straightforward way to ensure that is to request the lot of numbers of the color before they pour.

Color Hardener: An alternate way to color concrete is to use a shake-on color hardener.

Butterfield Color Perma-Cast Shake-on Color Hardener is broadcast on the concrete during the initial stages of the finishing process. It is worked into the surface to create the base color.

Not all contractors use color hardeners, so discuss this with your contractor before choosing colors

Color hardener will create a base color similar to the integral color but has additional coloring options and a hardened, denser surface.

Release Color

The release agent keeps the stamp from sticking during the stamping process. The release agent will also offer an accent color to the concrete once washed and sealed.

When picking the release color, use a color that accents your base color. Usually, a darker release agent over a lighter base color works best.

Stamping

The texture and pattern are created as the tool is pressed into the concrete. As the imprinting tool is pressed into the concrete surface, a portion of the colored release agent is embedded into the textured surface of the concrete.

Washing & Cutting

We typically discuss the saw cuts’ location with you before pouring the concrete so that you are prepared once we begin. Once the area is thoroughly cleaned, you will see the integral color with accents of the release color.

However, the final colors will only appear once the concrete is sealed and fully cured.

Sealing

Knowing this, we use a non-slip additive when sealing, which is recommended for exterior applications. If you are looking for more of a matte finish, there is a flattening paste available.

Stamped Concrete Maintenance

Maintaining your newly stamped concrete is important. Here are some key items to maintaining your concrete:

- Periodically inspect cured and sealed surfaces for wear or damage.

- All concrete curing and sealing compounds will eventually exhibit the effects of weathering and traffic.

- Wipe up all chemical solvent or petroleum spills for maximum coating life and performance as soon as possible.

- Remove abrasive debris by sweeping or vacuuming.

- Do not drag, drop, or place sharp edges on sealed surfaces.

- Periodic washings with mild detergents will help maintain surface luster.

- Do not use solvent or acid-based cleaning materials for general cleaning.

- Hot car tires, or turning tires while the car is standing, may damage the sealer.

- Surfaces subjected to car traffic, de-icing salts, or chemical exposure may exhibit wear more quickly.

- In most cases, stamped concrete does not need to be sealed yearly.

- A build-up of sealer can cause delamination issues. A Polyurethane sealant will give you several years of use until it needs sealant again.